Engine – What To Consider When Replacing Your Camshaft

Upgrading your camshaft is one of the most common and most efficient power upgrades you can do to your 22R/RE engine, however, what many people do not know is that there are a few things to consider if you are going this route.

Some considerations you need to have:

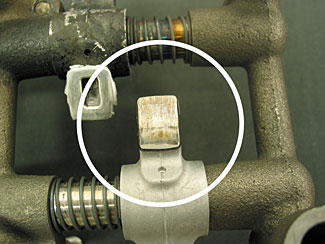

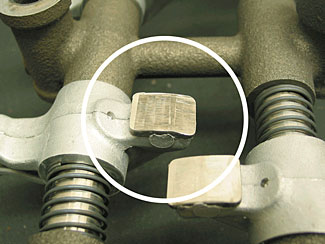

- Rocker Arms: LC Engineering strongly recommends replacing the rocker arms when a new camshaft is installed. The main reason is that the rocker arm will wear or "burnish" before the camshaft lobe will. When replacing a camshaft and not replacing the rocker arms, the new camshaft will contact the used rocker arms in a different spot and create an un-even surface for the camshaft lobe. In most cases, the two burnish marks will overlap and cause scoring and eventually lead to camshaft failure. It is possible to resurface the rocker wear pads but it is not recommended. A lot of the time the "burnish" mark is too uneven or deep and cannot be saved. If the "burnish" mark is all the way across the wear pad, the rocker arms will need to be replaced. Resurfacing the wear pads will also remove the heat-treating making the face of the rocker soft, not to mention it changes the geometry as well as the ratio of the rocker arm. There are photos below that will show some examples of normal wear and abnormal wear. Please contact our Technical Department for further information.

How an abnormal wear pattern looks on a rocker arm wear pad.

How an extremely worn rocker arm wear pad looks.

Adjustable Cam Gear: Adjustable cam gears are generally used to correct camshaft timing after the head has been milled or when the block has been decked. Cam gears are an effective way to “dial-in” a camshaft by advancing the cam for more low-end power or retarding the cam for more top-end power.

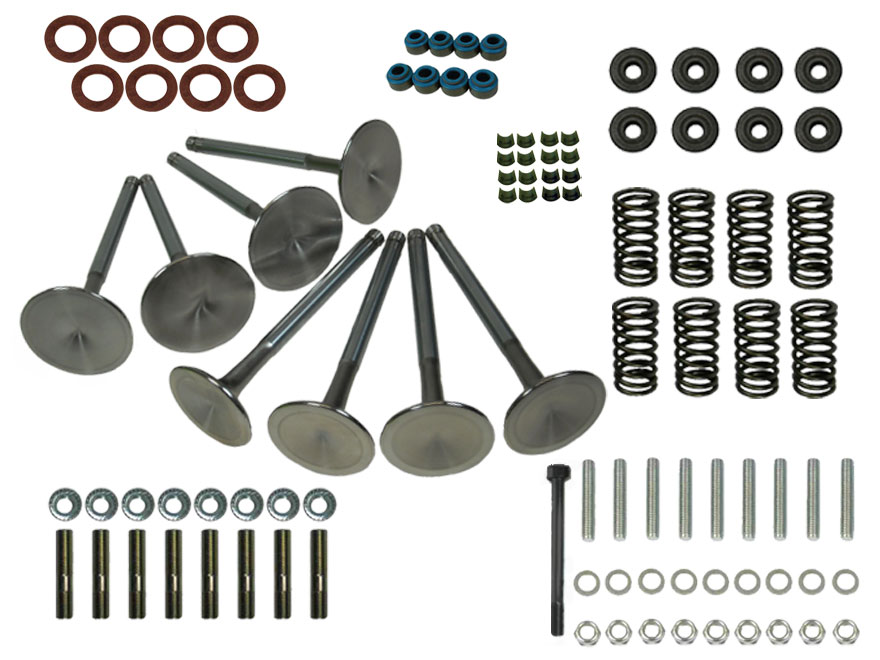

Valve Train (Valves, Seals, Springs, etc): Choosing the correct camshaft and matching valve train components is crucial for maximum performance as well as reliability. In order to have a good working top end, all of your components should be matched to each other. For example, your valve springs should match the lift of the cam so the valves can open and close how they are intended to with proper retainers.

RPM: When selecting your camshaft, you should have in mind, what you will be using the vehicle for. For example, if you are driving the vehicle everyday, there is no point of getting a cam that starts making power around 4,000 RPM. Always find the best power range for your specific application, bigger lifts are not always better.

Valve-Piston Clearance: One of the most important details that is often overlooked is piston to valve clearance. If you do not consider this when going to a higher lift cam, the piston could hit the valve and damage the engine. To avoid this, check your clearance and notch your pistons if necessary.

Fuel Management: Either on carbureted or on fuel injected applications, fuel management is something that will have to be addressed at some point depending on your cam selection and your power upgrades. On carbureted applications, it can go from re-jetting the carburetor to having to replace the carburetor for a bigger one. On EFI applications with bigger lift cams, the computer will need to be replaced since the 22RE computers offer very little room for tuning.

NOTE: Before removing your camshaft, make sure it rotates freely in your cylinder head.

|