Top Shift T-Case Conversion

(Kit B)

When doing a top shift conversion on a forward shift T case, you will need a block off plate to block off the old (unused) hole in the transmission that the forward shift shifter was in. In addition to that you will also need a new top shifting shifter to shift the new T case. That is why we have put kit B together for you, this is the perfect kit for a guy who is going to run a dual case setup.

Kit Includes:

- (2) Shift Rails

- (1) Shift Fork

- (1) Shift Fork Tube

- (2) Roll Pins

- (1) T-Case Shifter Kit

- (1) T-Case Block Off Plate

- (2) Gaskets

| Note: Images are for illustration purposes only. Images may not represent the product listed. Please contact customer service with any questions or concerns: 1-928-505-2501. |

by Trail-Gear

- OEM Forward Shift T-Case Applications

Tools Needed:

- ⅜ Ratchet

- 12mm, 14mm, 30mm Sockets

- Air Wrench

- Needle Nose Pliers

- Hammer

- Grinder

- Grinder

- 3/16 Diameter Pin Punch

- Snap Ring Pliers

- 6mm Allen Wrench

- Gasket Scraper

- Flat Blade Screwdriver

- Adjustable Wrench

- Permatex Ultra Grey Silicon

- Axle Grease

Installation Instructions:

1. Remove 30mm rear output flange nut and slide the flange off the output splines.

2. Remove speedometer sender bolt.

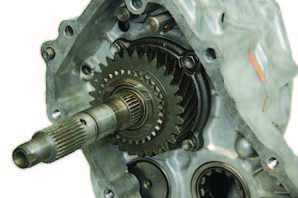

3. Remove speedometer sender.

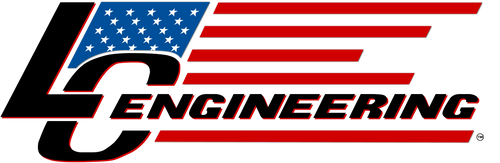

4. Remove the 7 bolts holding housing #4. Pull off the housing and remove.

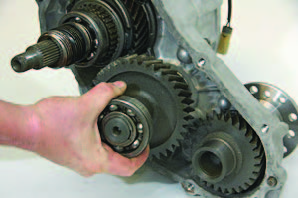

5. Using snap ring pliers, remove outer snap ring from the 4wd idler shaft bearing.

6. Remove the 10 bolts holding housing #3 and slide the housing out.

7. Remove 2 oil galleys by gently pulling them straight out.

8. Remove the front output idler gear.

9. Remove speedometer drive gear.

10. Remove oil pump gear and lock ball.

11. Remove 63/28N bearing from rear main shaft.

12. Shift into 2wd high. Remove 2wd/4wd shift fork roll pin with 3/16" pin punch.

13. Remove 2wd/4wd shift hub.

14. Remove 2wd/4wd shift collar & fork.

15. Slide off front output gear from output shaft.

16. Remove pair of cage bearings from output shaft.

17. Remove thrust washer & locking ball.

18. Unbolt and remove remove shifter base or block off-plate depending on model.

19. Remove 4wd light switch.

20. Using an Allen wrench, remove detent plugs from both sides of case. Rotate case on it's side, and tap case lightly to allow spring and ball to fall out.

21. Remove 2 bolts holding housing #1 on the passenger side of case

22. Remove last 2 remaining bolts holding housing #1 on the driver side of case.

23. Remove 2WD/4WD shift rail.

24. Remove snap ring from input shaft bearing.

25. Remove snap ring from idler shaft bearing.

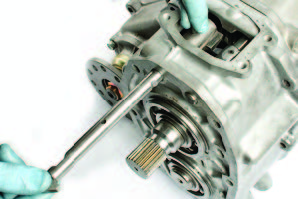

26. Using a pin punch, drive out roll pin from hi/lo shift rail.

27. Remove hi/lo shift rail.

28. Slide housing #1 forward and remove. Retrieve two shift fork roll pins from bottom of housing.

29. Remove input gear.

30. Remove counter shaft gear.

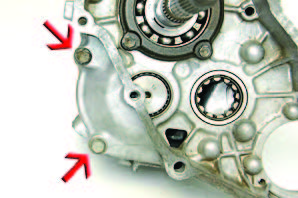

32. Remove hi/lo shift fork and shift collar.

32. Turn transfer case upside down and remove shift fork interlock pin from detent plug hole.

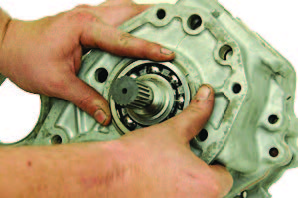

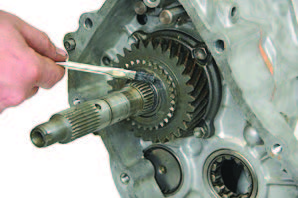

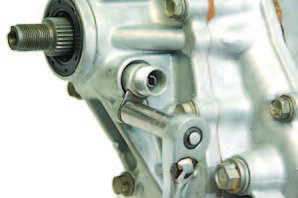

33. Insert roll pin into low range shift fork. Shaft can go in two ways, install as shown above. Notice position of notches on shift rail during assembly.

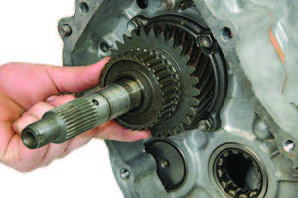

34. Place the clutch sleeve into the shift fork and slide fork in to place.

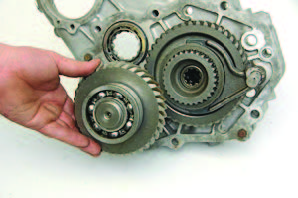

35. Install counter shaft gear/bearing assembly as shown.

36. Install input gear/bearing assembly in to main shaft.

37. Apply Ultra Gray (recommended) or place the new gasket on to housing section #2.

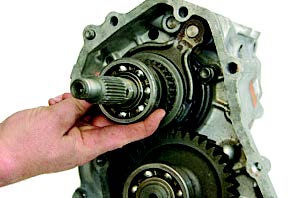

38. Slide housing #1 in to place and install bolts as shown. Using a rubber hammer, apply gentle pressure to seat housing.

39. Turn the transfer case around and install two more bolts on the other side.

40. Install the outer snap ring on input gear bearing.

41. Install the outer snap ring on countershaft bearing.

42. Insert interlock pin in to the driver side detent hole. If installing a twin stick shifter skip this step. Turn the case on it's side to assist in getting pin to drop in to place.

43. Make sure the interlock pin is all the way into position. Here the end of the pin can still be seen through the shift fork hole. Adjust position of shift fork until the pin can go all the way out of view.

44. Install shift rail and shift block.

45. Using a 3/16" pin punch to drive high low shift fork pin in to place.

46. Apply grease to ball hole on main shaft.

47. Place ball in to ball hole on main shaft.

48. Align thrust washer with lock ball and slide in to place over the ball. Grease to face of thrush washer once in place.

49. Grease to inside and outside of output shaft cage bearings. Slide bearings in to position on main shaft.

50. Install front output drive gear on to main shaft.

51. Grease the outer face of front output drive gear.

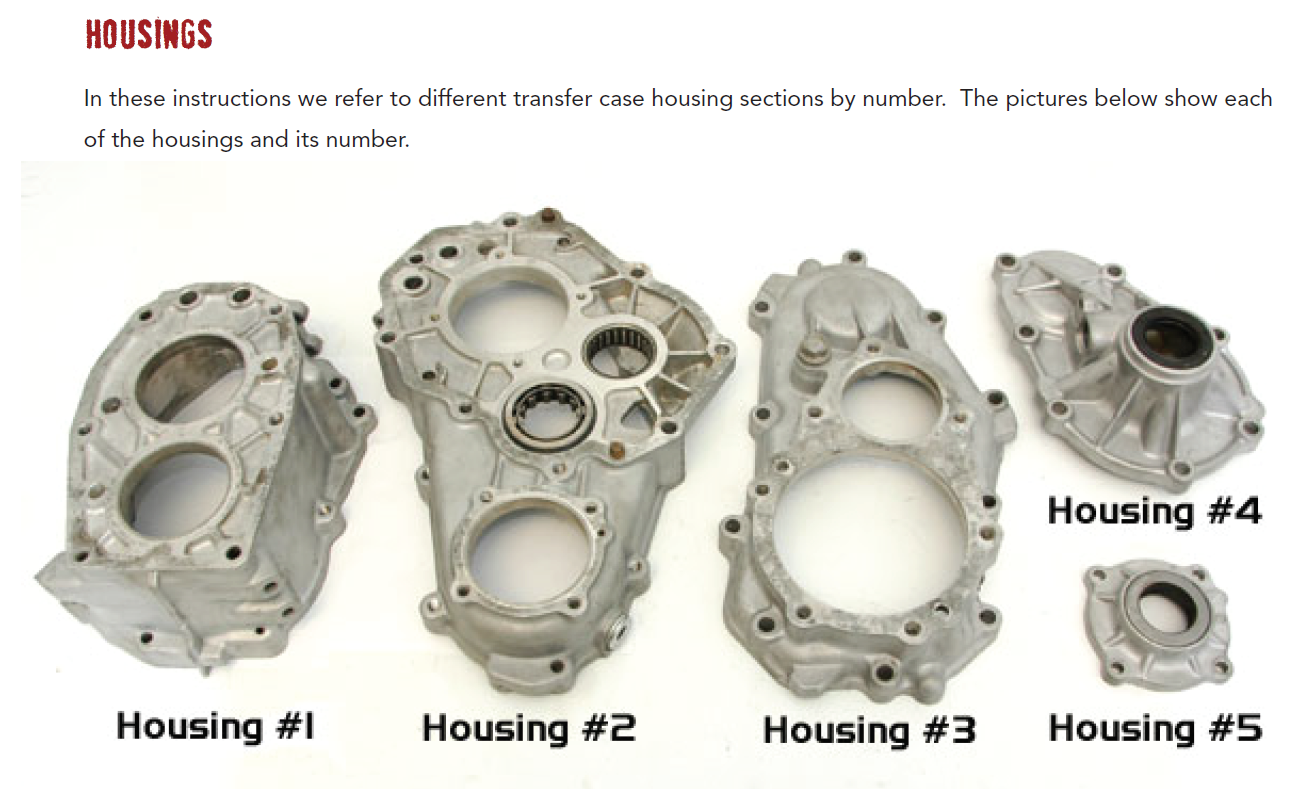

52. Slide clutch hub in to place on the main shaft.

53. Place clutch sleeve in to the shift fork. Slide shift fork and clutch sleeve in to case.

54. Using a 3/16" pin punch, drive shift fork roll pin down until it is flush with the fork.

55. Reinstall front drive idler gear.

56. Install output shaft rear support bearing.

57. (Optional) Using a screwdriver, remove and replace oil pump seal inside the oil pump drive gear.

58. Slide oil pump drive gear onto main shaft until it seats on bearing.

59. Apply grease to ball hole. Place ball into hole.

60. Align notch in speedometer drive gear with ball on main shaft. Slide speedometer drive gear onto main shaft.

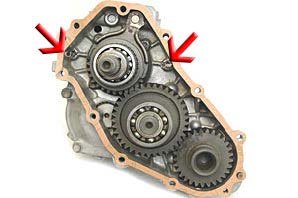

61. Apply Ultra Gray (recommended) or place new gasket on to the back of housing #2. Reinstall oil delivery tubes at arrows.

62. Apply grease to cage bearing in back of housing #3.

63. Install housing #3 on to the back of housing #2. Align oil transfer tubes with slots in the back of housing #3. Install 10 bolts into cover #3. Torque to 30 ft/lbs.

64. Install outer snap ring on idler bearing.

65. Apply Ultra Gray (recommended) or place new paper gasket on to back of housing #3.

66. Remove old output seal on housing #4. Install new seal and apply grease to inner lip.

67. Install housing #4 on to the back of housing #3. Install 7 bolts into housing #4. Torque to 30 ft/lbs.

68. Slide speedometer sender into housing #4. Install speedometer lock tab and bolt, torque to 10 ft/lbs.

69. Rotate case so it is on it's side. drop in one detent ball.

70. Next drop in one detent spring.

71. Apply a small amount of silicon to the threads of the detent plug and install. Flip case over on to the other side and install the ball, spring and plug as above.

72. Install 4wd shift light switch into housing #1.

73. Apply ultra gray Silicon to the inside splines of both flanges. Slide flanges in to place on t-case.

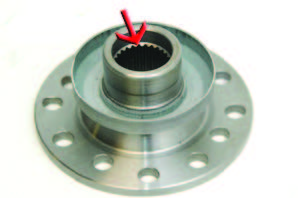

74. Install the main shaft nuts and washers. Tighten each nut to 90 ft/lbs. Using punch, stake nuts into the main shaft as shown.

Transfer Case Oil:

After installing the transfer case, remove the rear fill plug and fill with 80/90W GL5 gear oil. Once oil starts leaking out of the fill hole, the transfer case is full. The transfer case oil level should be checked after 10 miles of driving and topped off as necessary. Conventional or synthetic oil may be used.