Pro Head Studs

The ARP Cylinder Head Stud Set is a must for engines with increased cylinder pressure from high compression, nitrous oxide, turbocharged and supercharged applications. Made from 8740 Chromoly Steel, these studs test out at over 190,000 psi Tensile Strength. Stock replacement Cylinder Head Bolts are available too! On stock engines, LC Engineering always recommends replacing the old stretched head bolts with new ones to ensure the correct head torque.

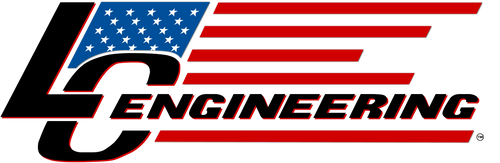

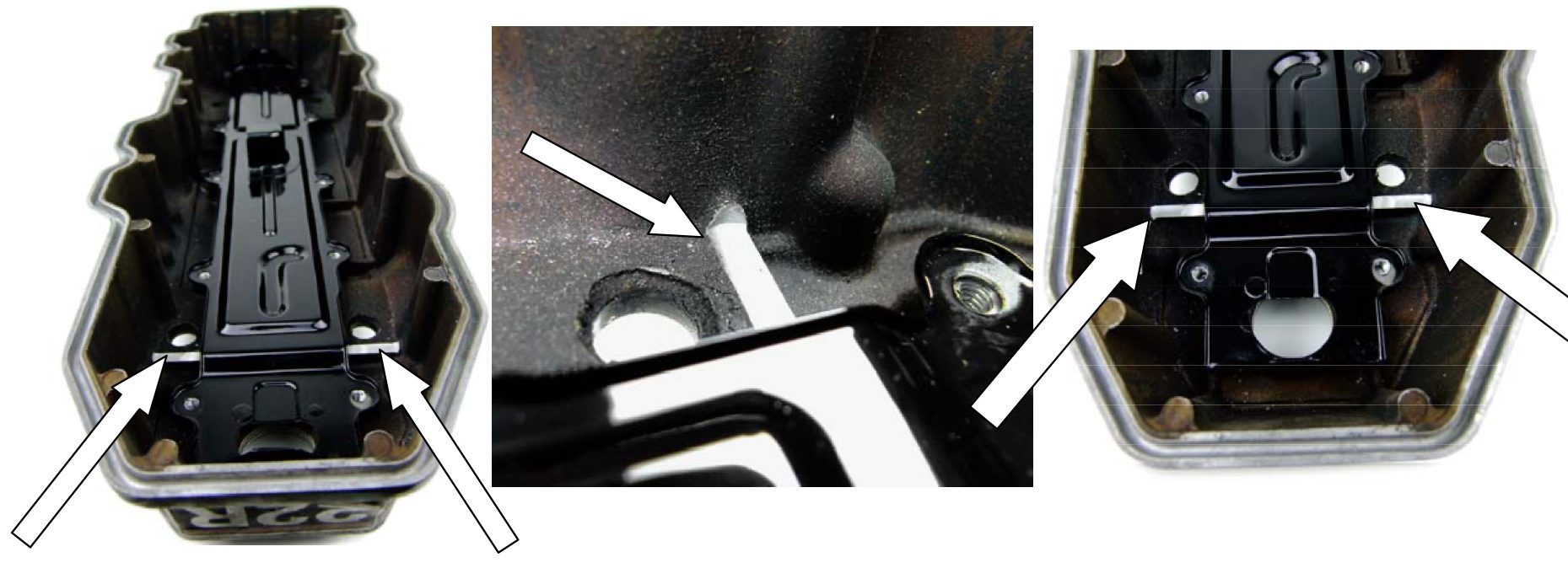

NOTE: The valve cover will need to have the two front gussets clearance to allow room for the head studs. If you prefer, we offer our LC Pro valve covers which will already have this modification here. These studs are utilized on the cylinder head to secure your cylinder head to your block, not your crankshaft. If you need crankshaft studs, see Part #: 1013102. Sold as a set of (10).

| Note: Images are for illustration purposes only. Images may not represent the product listed. Please contact customer service with any questions or concerns: 1-928-505-2501. |

- 1975-1980 20R 2.2L Engines

- 1981-1995 22R 2.4L Engines

- 1983-1995 22RE 2.4L Engines

- 1985-1988 22RET 2.4L Engines

To open a printable PDF version of this instruction CLICK HERE

Installation Notes

- The engine block and cylinder head decks must be flat and have the proper surface finish for the head gasket used or gasket failure may result.

- To ensure proper thread engagement and accurate torque readings, clean all threads in the block to remove remnant sealer, lubricant and debris. Chase if necessary with ARP Thread Chaser, part number 912-0006 (M12 x 1.25)

- Before final assembly, a mockup of the engine and or components is recommended to check the fit and clearance near and around the fasteners.

- Check valve cover clearance! It may be necessary to clearance the valve cover above the front 2 studs/nuts.

- Exceeding factory clamp load will distort the cylinder bore. Torque plate honing will counteract this distortion and ensure proper bore geometry for optimum performance/longevity. Torque plate honing should be performed using the same hardware, lubricant and torque as at final assembly.

- In some cases it may be necessary to trim the two front gusset to allow room for the front two head studs. You can check for clearance by installing the valve cover without any gasket. Another solution to this problem is to run the LC pro valve cover as this is already done to all our covers. (Pictures shown below also display the valve cover baffle modification in order to run the LCE Dual Row Timing Chain Conversion Kit)

Installation:

- Place the gasket and cylinder head in position on the engine block

- Screw the studs into the engine block The hex broach in the end of the stud is designed to assist with installing/removing the studs from the block, not for applying torque.

- Apply ARP Ultra-Torque Lubricate the stud threads and bottom of each nut with ARP Ultra-Torque Fastener Assembly Lubricant. Install the nuts and tighten hand tight.

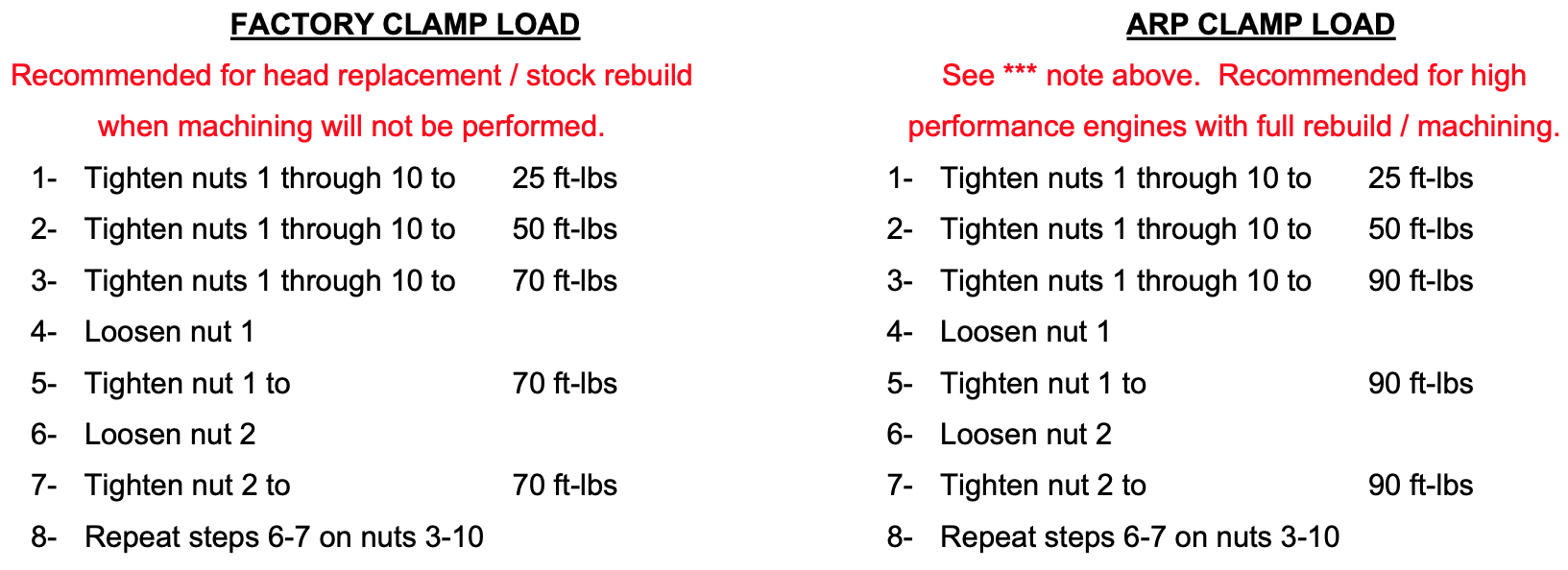

Torque Procedure: (Following the manufacturers recommended torque sequence, select FACTORY OR ARP clamp load and torque nuts per steps below)

18 Reviews Hide Reviews Show Reviews

-

i would always recommend lce

*****

-

Best quality out there, and a great deal

haven’t found ARP’s for the 22re’s for cheaper, arrived on time and in great shape.

-

Pro Head Stud Set

Excellent quality. I am ready for the next project, a lC turbo kit.

-

.

Overall excellent

-

.

.

-

All nuts and bolts accounted for

Usually a few business days to get here in washington state.

-

.

Very well built looks like they will hold up and are nice and heavy.

-

.

.

-

Absolutely perfect

I highly recommend if you're replacing head fasteners this is the way to go even for daily applications.