Dual Comp Clutch Kit (10")

All of LC Engineering's clutch kits feature all new components with a single diaphragm H.D. pressure plate. Don't be fooled by fancy spinning gizmos. A diaphragm clutch delivers full holding power at all engine rpm's. Our Dual-Comp Clutch Kit was developed for both street and off-road racers requiring a more aggressive clutch without giving up every day drive ability. The key to this kit is the clutch disc. One side has metallic pucks for a positive hold and the other has our Pro clutch fiber lining providing a smoother engagement to retain drive ability. Clutch kits come with the pressure plate, clutch disk, pilot bearing, throw out bearing, and a new alignment tool.

|

LCE DUAL COMP CLUTCH KIT

|

||

|

Pressure Plate

|

Torque Limit Ft. Lbs. | Horsepower Limit |

| LCE PRO 2100 Lbs. | 385 Ft. Lbs. | 385 HP |

NOTE: We recommend this for street vehicles with high horsepower engines. This clutch is stiffer than stock, but not as stiff as our metallic clutch kit. Not compatible with TDI conversions.

| Note: Images are for illustration purposes only. Images may not represent the product listed. Please contact customer service with any questions or concerns: 1-928-505-2501. |

- 1995-2004 5VZ 3.4L Engines

To open a printable PDF version of this instruction CLICK HERE

Installation:

-

1. Always disconnect the negative battery cable prior to doing any major work on your vehicle.

2. When removing your old clutch, note which way the clutch disc was facing (spring pack facing engine or transmission). You will want to install the new disc with the same orientation as the old disc you removed.

3. Before installing your new clutch clean the inner bellhousing area to make sure no debris gets onto the new clutch. Also inspect clutch bar for any damage (cracks, excessive wear etc...).

4. Remove flywheel and either resurface or replace. The flywheel must have a fresh surface for the clutch disc to mate to! Failure to resurface the flywheel can result in shorter clutch life and abnormal wear or vibration. If the flywheel is discolored from excessive heat, you may need to replace it.

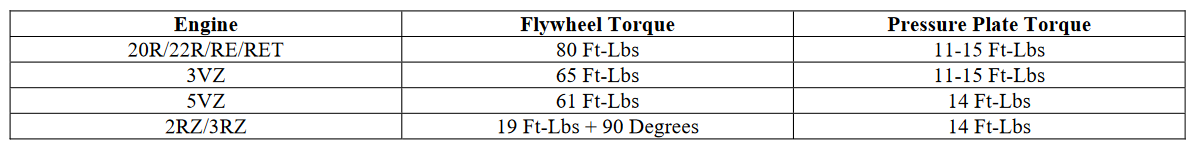

5. Install flywheel using a small amount of Loctite on the flywheel bolts. Torque the bolts in a star pattern. See the chart below for proper torque specs. 2RZ/3RZ flywheel bolts can not be re-used! These are a torque-to-yield bolt that are only intended to be torqued down once. New flywheel bolts are available from LC Engineering.

6. Install new pilot bearing in crankshaft. Failure to replace pilot bearing can result in annoying squeal noises when cold. We supply a new pilot bearing in all of our clutch kits.

7. Place clutch disc on flywheel, using the supplied alignment tool to make installation of the transmission easier. For all 20R, 22R, 22RE, 22RET, 2RZ, and 3RZ clutches, the spring side of the clutch disk faces the pressure plate/transmission. For 5VZ V6 clutches, the spring side faces the flywheel. If there is any confusion refer back to which way the stock disc was facing.

8. Install pressure plate onto flywheel, making sure to align the dowel pins in the flywheel with the corresponding holes in the pressure plate. Verify that the alignment tool keeps the clutch disk centered in the assembly (do not let the tool just hang on its own, you need to keep it centered as you install the pressure plate. Torque bolts evenly a little at a time in a star pattern. If the pressure plate is not torqued evenly in steps it can cause the plate to warp, this will not be covered under warranty. LC Engineering recommends tightening the pressure plate with hand tools only. Refer to chart below for torque specs. Remove alignment tool.

9. Replace throw-out bearing. The throw-out bearing is held in with two retaining clips that hold it to the clutch fork.

10. Lubricate all moving parts; input shaft, pressure plate "finger" tips, throw out bearing contact surfaces etc... with white lithium grease or Anti-sieze. This will ensure smooth performance and engagement of the clutch

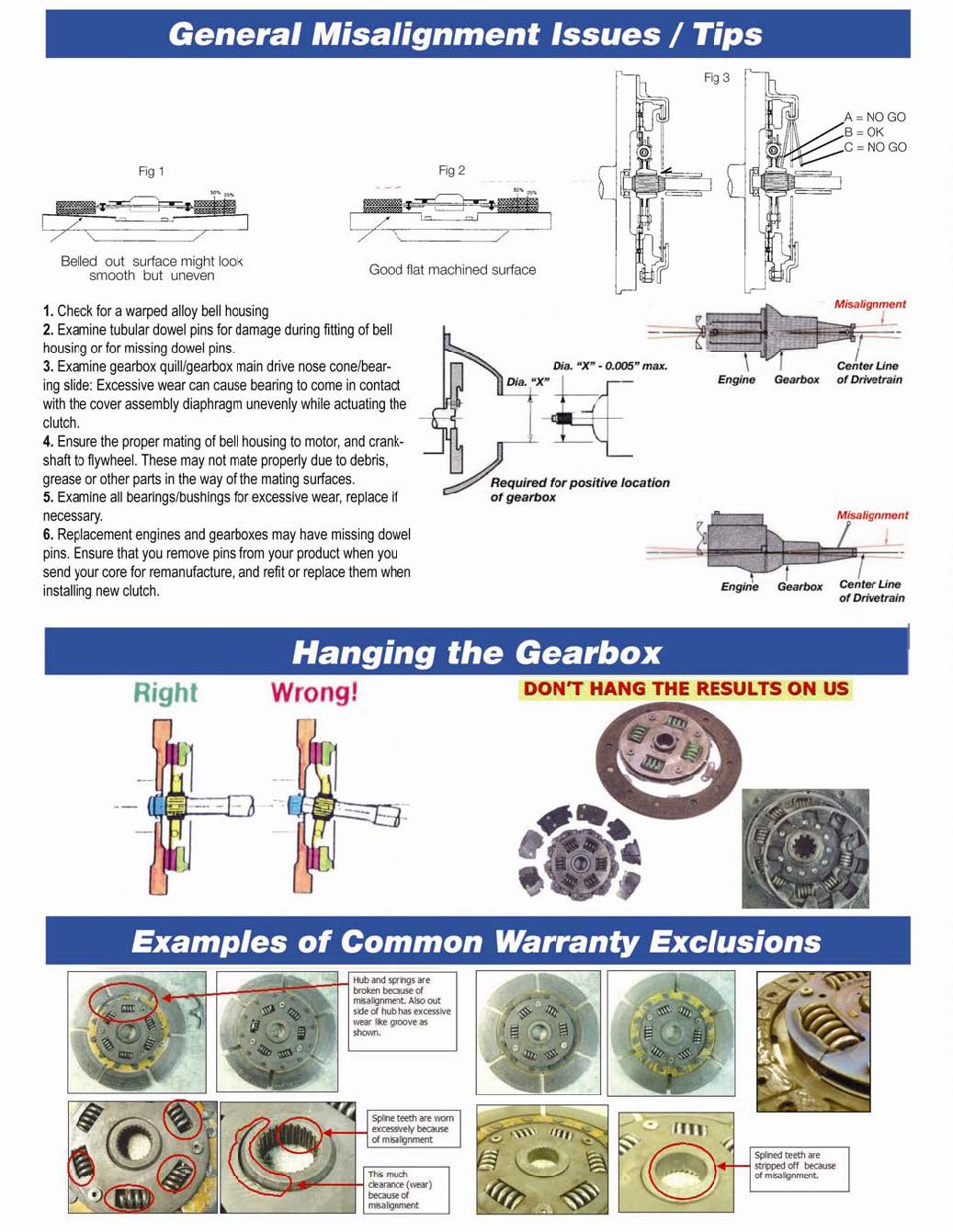

11. With the new throw out bearing in place, slide the transmission onto the engine, being extremely careful not to let the weight of the transmission hang on the clutch disk. This can cause serious damage to the disk. With the clutch disk properly aligned during installation, the input shaft should not require any force to install. Rocking the transmission or turning the output shaft as you install the tranny may help if it doesn't go in all the way. DO NOT USE THE BELLHOUSING BOLTS TO DRAW THE TRANSMISSION AND ENGINE TOGETHER! This can result in serious damage, especially to the new clutch or the thrust bearings inside the engine, and should not be necessary if everything is installed and aligned properly.

12. Re-install slave cylinder and other components you may have removed to gain access to the clutch.

13. If needed, bleed clutch hydraulic system according to repair manual.

14. Road test vehicle, avoiding aggressive driving for the first 500-750 miles. Proper break-in procedure is crucial to long service life out of your new clutch.

NOTE: FAILURE TO FOLLOW PROPER INSTALLATION OR BREAK-IN PROCEDURES WILL VOID ANY WARRANTY

7 Reviews Hide Reviews Show Reviews

-

Perfect Clutch

I was concerned this would be too firm or un-drivable / poor drivability. Nope, totally awesome! Almost a non event in a good way. I swapped from automatic so never felt stock pedal pressure, but this is not bad. Probably similar to +1 compared to my 97 stock nissan hardbody. Holds 10psi from a Gt3582r turbo on 35" tires and 4.56 gears (4x4). Also using the LCE Heavy 38lb flywheel and new Bolts kit. All this stuff is perfect, no complaints!

-

Exactly What I was looking for!

Super strong clutch. Have just over 7,000 miles on it now and its great for daily driving and to go wheeling. Love this clutch setup with my 35s. Be sure to run the 3vz throwout bearing if you are running the 5vz motor with the 3vz r150f.

-

Smooth and holds

This clutch is only slightly more aggressive than stock. Pedal feel is the same, but it does want to bite harder aka need to give it like 5-10% more gas than normal when taking off from a standstill. Its really minimal the difference and would recommend to all. Holds the power great on 33s.

-

Love it but need more time

So far the holds the power im putting down. Still pretty easy on it cuz im still breaking it in. But no slips holes firm and easy to drive. I recomend this to anyone looking for a clutch

-

Great hold, ok life

My Tacoma is turbocharged pushing 9 pounds with methanol injection. I race around all over town having fun all the time, but I rarely burn my clutch out doing pulls from a dig and always make a conscious effort to rev-match when shifting and this clutch lasted me almost 4 years before wearing down to the rivets. I would expect more life considering my diving habits, but oh well. Since I’m at about 290 HP at the crank, I’m going to get the tier clutch right under this one (Pro Clutch Kit rated for 300 HP) and see how the life of that compares.

-

Supercharged and 35" mud tires.

After talking with an employee and explaining my needs and the modifications I had done to my truck, I was pointed in the direction of this clutch. It is what is says, dual composite, having normal clutch friction material on the pressure plate side, and a semi metallic material on the fly wheel side. It's only been in the truck for about a hundred miles, so I haven't really seen the effects of really running the truck hard, but I feel confident it will handle it just fine.

-

great customer service

The clutch looks like it should ,built like a sh&T house :)