Pro Head Studs

Cure that head gasket problem on your 3VZ once and for all! Our exclusive 3VZ head studs made by ARP are much better than using another set of stock head bolts that are the torque to yield type. Combine these studs with a set of MLS head gaskets, and you won't have to worry about popping head gaskets ever again! The ARP Cylinder Head Studs are made from 8740 Chromoly Steel; these studs test out at over 190,000 psi Tensile Strength. If you're rebuilding your engine, LC Engineering always recommends replacing the old stretched head bolts with new ones to ensure the correct head torque. The torque for the stud's nut is 80 foot-pounds with molly lube. Studs are installed in the block snug tight no torque spec on the stud itself.

NOTE: Parts are for the single overhead cam engines only. Will Not Work on Camry Engines 3VZ-FE. Sold as a set of (16).

| Note: Images are for illustration purposes only. Images may not represent the product listed. Please contact customer service with any questions or concerns: 1-928-505-2501. |

- 1988-1995 3VZ 3.0L Engines

To open a printable PDF version of this instruction CLICK HERE

Installation:

- Chase all thread holes before installing. Use a 11mm x 1.25 tap to clean threads in the block. Be sure to clean all shavings out of thread holes and block prior to final installation.

- LC Engineering recommends installing the head gaskets and heads before you install the studs into the block. This will keep the stud threads from cutting into the head and causing aluminum flakes to fall into the engine.

- Using a small amount of Blue Loctite on the block side threads, install head studs in block with 3/16 allen wrench. Make sure studs thread all the way into the block. Snug hand tight (approx. 10ft-lbs). NOTE: Do not over-torque, the stud does not need to be very tight in the block. All torque is on the nut-end of the stud. Depending on your head/block decking and thread depth in the block you may need to loosen the stud from bottoming out in the block to verify that the nut gets full thread contact on top of the stud.

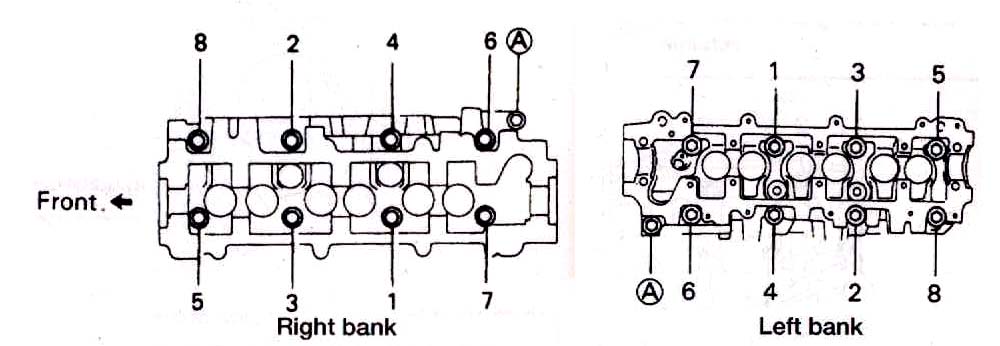

- Install washers and nuts on studs. Torque nuts to 80ft lbs using the ARP Moly or Ultra-Torque Lube supplied with the studs. Use a 3-step procedure to torque the nuts down. Start at approx. 20 to 30ft-lbs then goes to approx. 50 to 60ft-lbs then torque to the final 80ft-lbs. Be sure to use factory torque sequence as shown below.

8 Reviews Hide Reviews Show Reviews

-

Alberto Betancourt give 5 stars

-

Anonymous give 5 stars

Great customer service and fast shipping.

-

Studs

Quality is good, studs could be 3/16 longer, but worked. Hard to find item. LC came through for me.

-

It’s a must

Probably the best headstuds on the market , I wouldn’t trust anything else in my yota

-

.

.

-

VERY SATISFIED WITH PURCHASE

GREAT OVERALL EXPERIENCE- FROM THE ONLINE TECH ASSIST THRU DELIVERY- EVERYTHING EXACTLY AS ADVERTISED

-

Working good.

When installing the studs. Put the nuts on the top to make sure you don't thread the studs too far down.

-

3vze 3.0 head studs

Accurately represented and speedy on time delivery. Exactly what I was looking for. Thanks for the help.