Pro Stroker Crankshaft

LC Engineering's stroker cranks are first sent through our inspection department to find any imperfections. After they pass the initial evaluation, they are Magnaflux inspected to verify the condition of the core. The crank is then hard-welded, and the journals are offset ground to get the 5mm extra stroke. The crank is then heat-treated and ground to our exact specs. The journals are micro-polished, and the oiling holes are chamfered. The final crankshaft is then balanced to finish out the process.

Features Include:

- 94mm Stroke

- Smoothed and Polished

- Chamfered Oiling Holes

- Shot Peened

- Micro Polished Journals

- .010" Main Journals

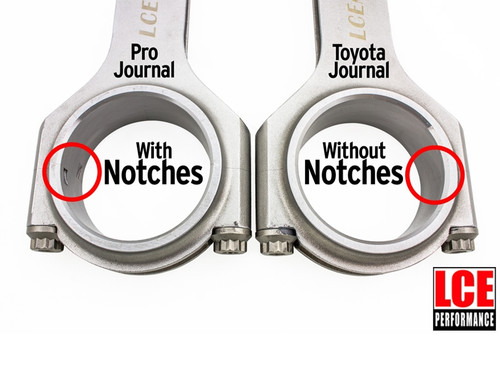

- Standard Pro Rod Journals

- Dynamic Balanced

- Magnaflux Inspected

- Heat Treated

| Note: Images are for illustration purposes only. Images may not represent the product listed. Please contact customer service with any questions or concerns: 1-928-505-2501. |

- 1981-1995 22R 2.4L Engines

- 1983-1995 22RE 2.4L Engines

To open a printable PDF version of this instruction CLICK HERE

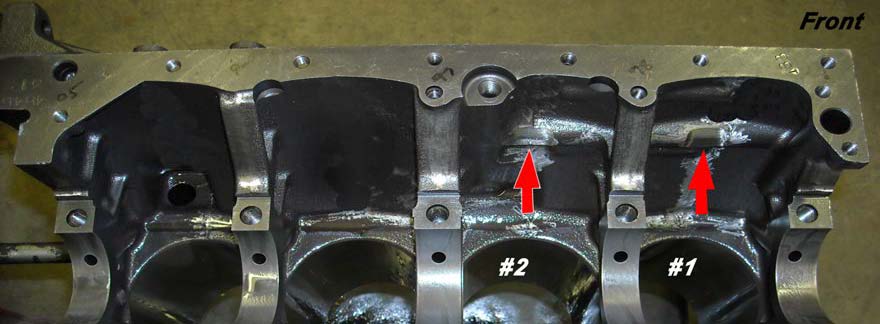

When installing any of the Stroker crankshafts care must be taken by the installer to verify proper rotating assembly clearances. The Oil galley on number 1 and 2 cylinders must be notched approximately .080" to .120" for clearance of the rod nut; this amount may differ between rod combinations. You should have a minimum of .030" clearance between block and rod bolts.