Outlaw Camshaft

Now here's the BIG DOG!! The .527" lift Outlaw cam is the biggest cam LC Engineering makes! This is a full race cam designed to be used with oversized valves and a highly modified cylinder head. This cam will give that 22R race engine power up to 8,000 RPM.

LC Engineering is constantly striving to improve both the quality and performance of our products. We test our camshafts on the street, race track and off-road. The results are an improved line of camshafts that offer a broader selection of grinds, increased horsepower, and higher quality. All LC Engineering Camshafts are ground on new billets and double heat-treated for long life. Each has been designed for maximum torque and horsepower, specifically for the application. When comparing camshaft profiles, always reference the duration @ .050" valve lift.

20R/22R - .527" Outlaw Camshaft

Circle Track / Drag Race (3000-8000 rpm range)

Side drafts, Holley 2-Barrel, 1 5/8" Header

|

|

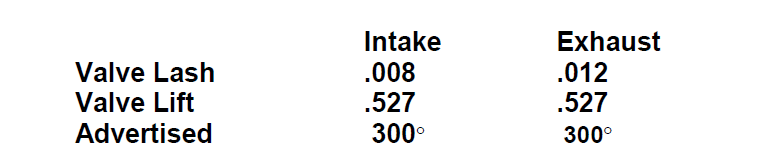

Intake | Exhaust |

| Valve Lash | .008 | .012 |

| Valve Lift | .527 | .527 |

| Advertised Duration | 300° | 300° |

| Duration @ .050" | 269° | 272° |

| Lobe Center | 105.5° | 107° |

| Lobe Separation | 106.25° |

|

Intake Opens 29° BTDC

Intake Closes 60° ABDC

Exhaust Opens 63° BBDC

Exhaust Closes 29° ATDC

NOTE: Will not work with the stock 22RE or 22RTE computer. It requires an aftermarket stand alone engine management system like one of these we offer:

- Haltech Elite 550 22RE Fuel Management System w/ Sub Harness Kit, see Part #: 1020220.

- Haltech Elite 550 22RE Fuel Management System w/ Complete Harness Kit, see Part #: 1020221.

- Pro Fuel Injection Kit #3 Naturally Aspirated 4 Cylinder, see Part #: 1063026.

NOTE: Always check the valve to piston clearance and valve to valve clearance with this camshaft! Piston notching may be required if you do not have .100" of valve to piston clearance at full lift. Failure to install this cam with matched valve train components can cause engine damage. LC Engineering highly recommends using our Pro Camshaft Kit to allow proper spring retainer to guide clearance for any cam that has over .450" lift or in any application that requires a sustained RPM of 6,000 or higher.

- Pro Camshaft Kit, see Part #: 1020000.

NOTE: LC Engineering will not warranty any cam damage if you do not purchase new Toyota rocker arms from LC Engineering, or a complete rocker arm assembly from LC Engineering at the same time as purchasing our camshaft.

Buyer beware on reground rockers in the market. Regrinding the pad on the rocker can remove the heat treated portion of the pad making for a soft rocker. Rocker arms that are reground will not have the factory geometry of a stock rocker. To regrind a rocker will take care of the face surface but will do nothing to address the rocker shaft bore, a loose rocker bore will make adjustment difficult and will never be correct which is why we cannot warranty a camshaft unless new rockers are purchased with a camshaft.

This product should not be used in a manner that violates Federal EPA Laws.

| Note: Images are for illustration purposes only. Images may not represent the product listed. Please contact customer service with any questions or concerns: 1-928-505-2501. |

- 1975-1980 20R 2.2L Engines

- 1981-1995 22R 2.4L Engines

- 1983-1995 22RE 2.4L Engines (w/ aftermarket engine management system)

To open a printable PDF version of this instruction CLICK HERE

This Camshaft must be installed with new rocker arms. LC Engineering will not warranty any camshaft that was not purchased together with Aluminum rocker arms. LC Egineering highly recommends using our Pro Camshaft Kit (Part# 1020000) or Double Spring & Retainer Kit (Part# 1023210) when running any cam with over .460" lift or in any application that requires a sustained RPM of 6,000 or higher.

The following figures taken @ .050 lift at valve with .000 valve lash.

Installation Notes:

- Always check valve to piston clearance and Valve to valve clearance with this Camshaft! Failure to install this cam with matched valve train components can cause engine damage.

- After installing a new camshaft, lash #1 intake valve to zero then screw intake valve in .080" (Valves not closing completely) with spark plugs removed turn engine over CAREFULLY BY HAND. Do intakes first, if OK then do exhaust. If engine cycles without binding, you are sure that you have minimum clearance (If binding occurs, piston clearance is required).

Camshaft Break-In Instructions

The first few minutes on camshaft and rockers are the most important wear period. In this period the cam and rockers become burnished together. When installing the camshaft, thoroughly coat the lobes with the special assembly lube provided. Cam should be installed per factory service manual procedures. Set valves at proper lash dimensions, and then readjust valves after break in period is completed. CHECK valve train for interference. CHECK valve to piston clearance, you must have .100" min. CHECK valve spring retainer to valve guide and seal for clearance. CHECK valve springs for coil binding, you must have .090" min. Of free travel before the springs become solid after the valve in fully open. 98% of all cam failure is excessive valve spring pressure.

Start engine quickly, excessive cranking of engine is not good for the camshaft. Bring rpm to 1500-1800 for 20-30 minutes (ABSOLUTELY NO IDLING & NO REVVING OVER 2000 RPM) during the break in period. Camshaft should now be burnished to the rockers. It is absolutely vital that once a cam lobe and rocker have been burnished together, they remain together. So if the camshaft and rockers are removed from the engine, be sure the rockers are numbered and reinstalled on the same lobe. Failure to do this is asking for disaster.

NOTE: Standard degreeing procedures should be followed for maximum performance.

All cam specifications are checked at .050" lift.

3 Reviews Hide Reviews Show Reviews

-

.

.

-

camshaft outlaw 1022018 (brad)

from los cabos mexico very good attention and availability

-

Sweet

Some nasty looking lift!!!